JIE intelligent transmission solution releases JIE intelligent transmission solution

complete information

Selection Guide for Planetary Gearboxes and Worm Gearboxes

Overview:

Planetary gearboxes excel in applications demanding high torque, precision, and compact size. Worm gearboxes are well-suited for applications requiring high reduction ratios, self-locking, and simple designs.

Gear reducers are the unsung heroes of industrial automation, transforming high-speed, low-torque motor outputs into the precise, powerful motion required for countless applications. Among the myriad of gearbox types available, planetary and worm gearboxes are two of the most common.

Structural Dissection

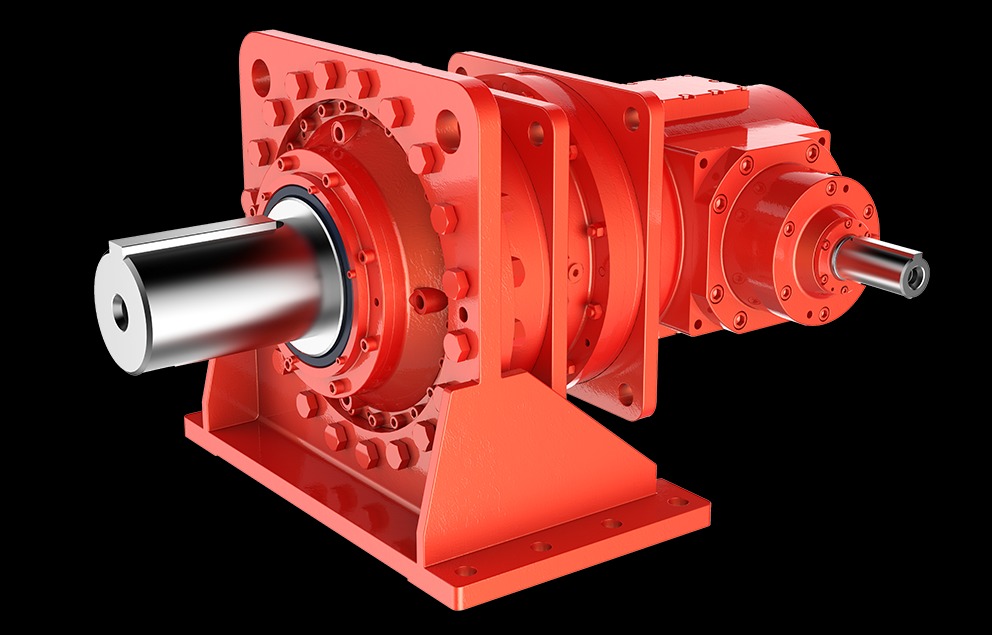

Planetary Gearboxes: Characterized by a sun gear surrounded by planetary gears, planetary gearboxes offer compact designs and high torque densities. The planetary gear set is typically encased in an outer ring gear.

Worm Gearboxes: Comprising a worm gear and a worm wheel, worm gearboxes are known for their high reduction ratios and self-locking capabilities. The worm gear meshes with the worm wheel at a helical angle.

Performance Parameters

To quantitatively assess the performance of planetary and worm gearboxes, we analyzed key parameters such as torque, speed, efficiency, and backlash.

Torque: Planetary gearboxes generally offer higher torque capacities compared to worm gearboxes of similar size, making them suitable for heavy-duty applications.

Speed: Worm gearboxes typically provide higher reduction ratios, resulting in lower output speeds. Planetary gearboxes, on the other hand, offer a wider range of speed ratios.

Efficiency: Planetary gearboxes generally exhibit higher efficiencies due to fewer meshing points and lower friction losses.

Backlash: Worm gearboxes often have higher backlash compared to planetary gearboxes, which can affect positioning accuracy.

| Backlash | Low | Higher |

| Size and Weight | Compact | Larger |

| Noise Level | Lower | Higher |

| Cost | Higher | Lower |

| Self-Locking | No | Yes |

Advantages and Disadvantages

Planetary Gearboxes:

Advantages: High torque density, compact design, high efficiency, low backlash.

Disadvantages: Higher cost, complex manufacturing.

Worm Gearboxes:

Advantages: High reduction ratios, self-locking, simple design, low noise.

Disadvantages: Lower efficiency, higher backlash.

Application Profiles

Planetary Gearboxes: Robotics, automation, aerospace, and medical equipment.

Worm Gearboxes: Material handling, conveyors, lifting equipment, and automotive applications.

Selection Guide for Planetary Gearboxes and Worm Gearboxes

1. Load Selection

Light Loads: Suitable for small devices, instruments, etc. Consider worm gearboxes or small planetary gearboxes due to their simplicity and lower cost.

Medium Loads: Ideal for general industrial machinery and automation equipment. Planetary gearboxes are often preferred due to their high torque density and load-carrying capacity.

Heavy Loads: For large machinery, cranes, and other heavy-duty applications, worm gearboxes are well-suited due to their self-locking feature and high reduction ratios.

2. Precision Requirements

High Precision: For CNC machines, robots, and other equipment demanding high positioning accuracy, planetary gearboxes are the preferred choice due to their low backlash and high precision.

General Precision: For ordinary industrial machinery, worm gearboxes can meet general precision requirements.

3. Operating Environment

Harsh Environments: For high-temperature, high-humidity, or corrosive environments, select gearboxes with special materials and sealing structures to ensure corrosion resistance and high-temperature tolerance.

Normal Environments: For general industrial environments, standard cast iron or aluminum gearboxes are sufficient.

4. Noise Levels

Low Noise: For medical equipment, laboratory instruments, and other noise-sensitive applications, planetary gearboxes are preferred due to their lower noise levels.

General Noise Levels: For general industrial environments, the noise levels of worm gearboxes are typically acceptable.

5. Other Factors

Installation Space: Consider the available installation space and select a gearbox with a compact design.

Output Shaft Type: Choose the appropriate output shaft type based on the connection method, such as solid shaft, hollow shaft, or flange output.

Lifespan: Select materials and manufacturing processes that meet the required lifespan of the equipment.

Cost: Consider the cost-effectiveness of the gearbox while ensuring it meets performance requirements.

-

Authenticated user

-

Authenticated user

JIE intelligent transmission solution releases JIE intelligent transmission solution

hot news

- Research丨Lv Tie, a researcher from the Academy of Social Sciences, visited JIE for research and guidance >

- Academician|Mathematician Academician Sun Binyong inspects JIE future factory >

- Research | Lu Wuhu, vice chairman of the Municipal Federation of Trade Unions, investigates the JIE future factory >

- Research | Li Yongwei, Director of the Technological Innovation Department of the Provincial Department of Economics and Information Technology, investigates the future factory of JIE >

- Research | District Science and Technology Bureau Secretary Cao Xiaoxiang investigates JIE future factory >

- 33 | There is a kind of happiness called party care >

-

- Sharing Center

- Member Sharing

- Exclusive Sharing

- Public Sharing

Official Website

Official Tiktok

Official WeChat

Copyright © 2022 Hangzhou Jie Drive Technology Co., Ltd. Zhejiang ICP No. 16044538-4

English

English 简体中文

简体中文

Official Tiktok

Official Tiktok Official WeChat

Official WeChat