JIE intelligent transmission solution releases JIE intelligent transmission solution

complete information

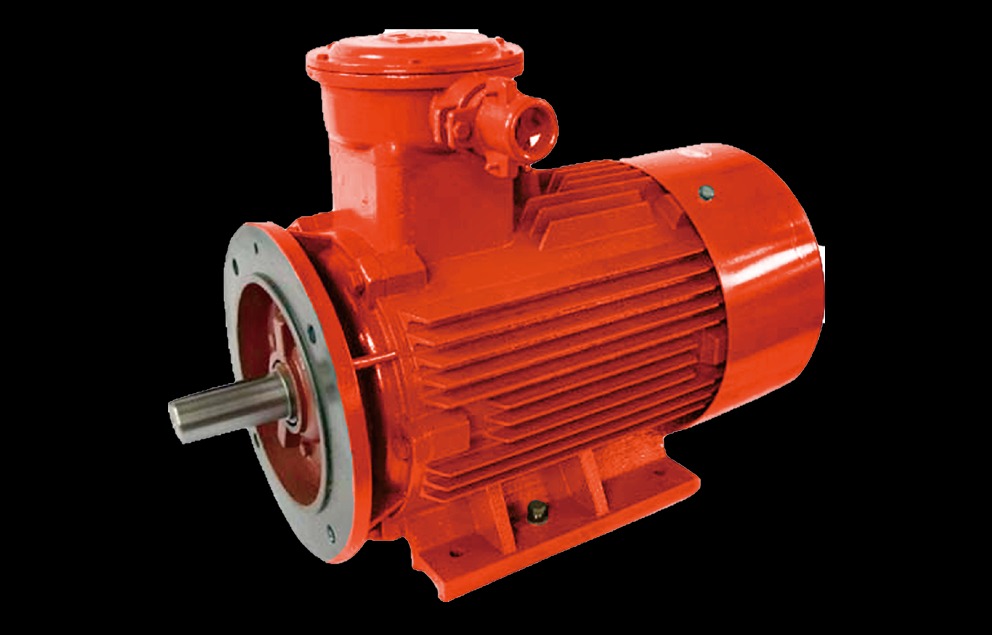

Intorduction of JD-B Explosion-Proof Motor

JD-B Explosion-Proof Motors are designed to operate safely in environments where there is a risk of explosive atmospheres, such as oil and gas refineries, chemical plants, and mining operations. These motors are specifically engineered to prevent ignition of flammable gases or vapors, ensuring safety and reliability in hazardous locations.

Key Features and Benefits:

Explosion-Proof Certification: Complies with international standards like IEC 60034-7 and ATEX, ensuring safety in hazardous areas.

Robust Construction: Built to withstand harsh conditions and vibrations, providing long-term durability.

Efficient Operation: Designed for optimal energy efficiency, reducing operational costs.

Various Applications: Suitable for a wide range of industries, including oil and gas, chemical processing, and mining.

Common Applications:

Oil and Gas: Drilling rigs, pumping stations, and processing plants.

Chemical Industry: Production facilities, storage tanks, and transportation systems.

Mining: Underground operations, ventilation systems, and material handling equipment.

Three-Phase Induction Motors: The most common type, offering reliable performance and efficiency in various applications.

Single-Phase Induction Motors: Used in situations where only a single-phase power supply is available.

DC Motors: Provide precise control and torque, often used in specialized applications.

Typical Technical Specifications:

Power Rating: Measured in horsepower (hp) or kilowatts (kW).

Voltage: Typically 380V or 440V, but other voltages are available depending on regional standards.

Frequency: Usually 50 Hz or 60 Hz.

Enclosure Type: Often IP65 or higher, indicating protection against water and dust.

Temperature Class: Determines the maximum ambient temperature the motor can safely operate in.

Duty Cycle: Specifies the motor's workload and rest periods.

Mounting Type: Options include foot-mounted, flange-mounted, or combination.

Cooling Method: Typically air-cooled, but liquid-cooled options are available for high-power applications.

Additional Considerations:

Certification: Ensure the motor complies with relevant explosion-proof standards (e.g., IEC 60034-7, ATEX).

Environment: Consider the specific conditions the motor will operate in, such as temperature, humidity, and corrosive substances.

Maintenance: Regular maintenance, including inspections, cleaning, and lubrication, is essential for long-term performance and safety.

-

Authenticated user

-

Authenticated user

JIE intelligent transmission solution releases JIE intelligent transmission solution

hot news

- Research丨Lv Tie, a researcher from the Academy of Social Sciences, visited JIE for research and guidance >

- Academician|Mathematician Academician Sun Binyong inspects JIE future factory >

- Research | Lu Wuhu, vice chairman of the Municipal Federation of Trade Unions, investigates the JIE future factory >

- Research | Li Yongwei, Director of the Technological Innovation Department of the Provincial Department of Economics and Information Technology, investigates the future factory of JIE >

- Research | District Science and Technology Bureau Secretary Cao Xiaoxiang investigates JIE future factory >

- 33 | There is a kind of happiness called party care >

-

- Sharing Center

- Member Sharing

- Exclusive Sharing

- Public Sharing

Official Website

Official Tiktok

Official WeChat

Copyright © 2022 Hangzhou Jie Drive Technology Co., Ltd. Zhejiang ICP No. 16044538-4

English

English 简体中文

简体中文

Official Tiktok

Official Tiktok Official WeChat

Official WeChat