JIE intelligent transmission solution releases JIE intelligent transmission solution

complete information

Gear Motor vs. Worm Gear Reducer - A Complete Analysis of Performance Differences and Application Scenarios

In the field of industrial automation, choosing the right power transmission device is the key to ensuring efficient and stable operation of the production line. Gear motors and worm gear reducers are two common power conversion devices, each with unique performance characteristics and a wide range of application scenarios.

一. Technical principles and structural comparison

Gear motor: Briefly describe the basic structure of the gear motor, including the gear set, motor and housing, and emphasize its principle of speed reduction and torque increase through gear meshing.

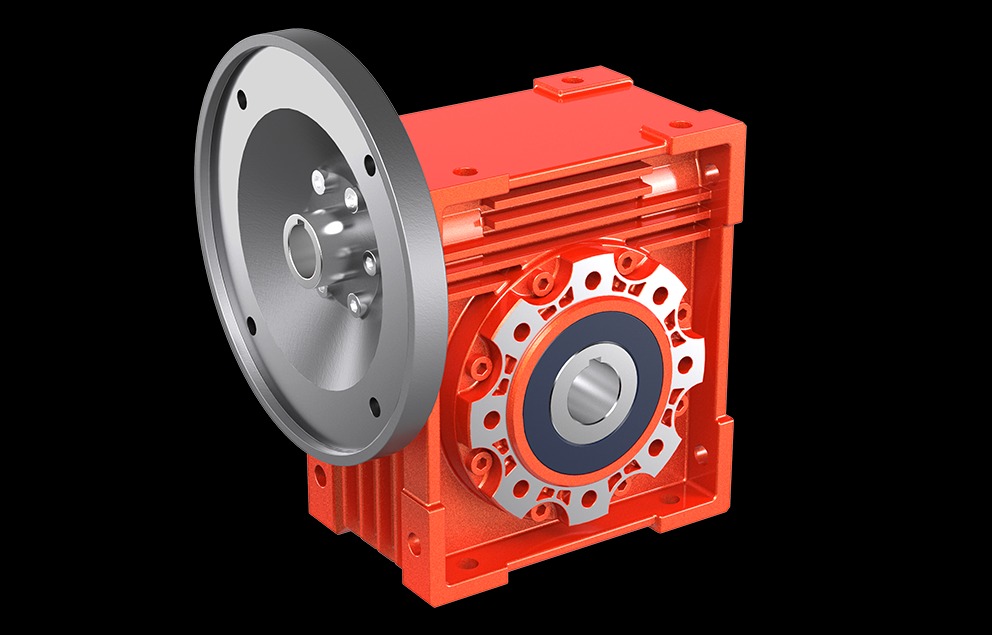

Worm gear reducer: Introduce the unique design of the worm gear reducer, including the interaction between the worm and the worm wheel, and analyze how it achieves the characteristics of large reduction ratio and high torque output.

二. Performance difference analysis

1. Transmission efficiency

Gear motor: Gear motors achieve power transmission through precise gear meshing, and their transmission efficiency is usually high, especially when running at medium and high speeds. This is due to the directness and efficiency of the gear transmission itself, which makes the energy loss relatively small. However, with the decrease of speed and the increase of load, the transmission efficiency may decrease.

Worm gear reducer: Although the worm gear reducer can achieve a large reduction ratio and stable torque output, its transmission efficiency is relatively low. This is mainly due to the large sliding friction between the worm and the worm wheel, and the easy wear of the worm wheel tooth surface, which leads to a large loss of energy during the transmission process. Therefore, in the pursuit of high efficiency, the worm gear reducer may not be the first considered choice.

2. Reduction ratio and torque output

Gear motor: The reduction ratio range of the gear motor is relatively wide, but it is usually not as large as that of the worm gear reducer. However, with a moderate reduction ratio, the gear motor can provide a relatively smooth torque output and a fast response speed, which is suitable for occasions that require rapid start and stop.

Worm gear reducer: The biggest feature of the worm gear reducer is that it can achieve a very large reduction ratio, usually up to dozens or even hundreds. This makes it have an incomparable advantage in occasions where low-speed and high-torque output is required. At the same time, the worm gear reducer also has a good self-locking performance, that is, when there is no external force, the worm cannot reverse drive the worm wheel, which is very useful in some specific applications.

3. Noise and vibration

Gear motor: Gear motors may generate certain noise and vibration during operation, which mainly depends on the processing accuracy, meshing condition and lubrication condition of the gears. However, by adopting high-precision gears, optimizing the gearbox structure and strengthening lubrication, the noise and vibration levels can be effectively reduced.

Worm reducer:

4. Maintenance and life

Gear motor: Gear

Worm reducer: The maintenance of worm reducer is relatively complicated, because the worm gear tooth surface is easy to wear, and it is necessary to regularly check and replace the parts with severe wear. In addition, the lubrication between the worm and the worm wheel also needs special attention to ensure good lubrication to reduce wear. Nevertheless, with the correct selection and maintenance, the life of the worm reducer can still reach the expected goal.

三 User Application Scenario Analysis

1. High-precision positioning and fast response

Gear motors show significant advantages in occasions where high-precision positioning and fast response are required, such as robot joint drive, precision assembly operations on automated production lines, and feed systems of CNC machine tools.

Advantages Analysis:

High Precision: Gear motors can achieve extremely high transmission accuracy through precise gear meshing, meeting the high-precision positioning requirements of robot joints, etc.

Fast Response: Gear motors have high transmission efficiency and fast response speed, and can quickly adjust the speed and torque to adapt to rapidly changing working conditions.

Reliability: Gear motors made of high-quality materials and advanced manufacturing processes have high durability and reliability, and can maintain stable performance during long-term operation.

Application Cases:

In the field of industrial robots, gear motors are widely used in joint drives to achieve precise movement and flexible operation of robots. For example, in assembly robots, gear motors can drive each joint to achieve high-precision positioning and grasping actions.

On automated production lines, gear motors are used in conjunction with servo systems to achieve precise material transmission and positioning, improving production efficiency and product quality.

2. Heavy load and low-speed operation

In scenarios that bear large loads and achieve low-speed stable operation, such as conveyor belts, mixers, cranes, and heavy machinery, worm gear reducers have shown their irreplaceability.

Advantages:

Large reduction ratio: Worm gear reducers can achieve extremely large reduction ratios, thereby outputting larger torques to meet the needs of heavy-duty working conditions.

Self-locking performance: Worm gear transmission has a self-locking characteristic, that is, when the worm stops rotating, the worm cannot rotate in the opposite direction by itself. This characteristic is particularly important in situations where reversal needs to be prevented.

Stability: The transmission of worm gear reducers is smooth, with small impact and vibration, which is conducive to protecting equipment and extending service life.

Application cases:

In conveyor belt systems, worm gear reducers are used to drive the drum to rotate and achieve smooth material transportation. Its large torque output capacity can ensure the stable operation of the conveyor belt under heavy load conditions.

In mixers, worm gear reducers reduce the speed and increase the torque, so that the stirring paddle can fully mix the materials, improve the mixing efficiency and product quality.

In the field of cranes, worm gear reducers are used to drive the hoisting mechanism to achieve smooth lifting and positioning of heavy objects. Its high load capacity and stability are the key to ensuring the safe operation of cranes.

3. Space limitation and installation convenience

For environments with limited space or complex installation conditions, gear motors and worm gear reducers have their own characteristics in terms of space utilization and installation convenience.

Gear motor:

Compact structure: Gear motors usually adopt a compact structure design, small size, light weight, and are easy to install in a limited space.

Easy to integrate: Gear motors can be easily integrated with other transmission components and control systems to form a complete power transmission system.

Worm gear reducer:

Diversified design: Worm gear reducers can be designed in a variety of ways according to actual needs, including hollow shaft, flange installation and other installation methods to adapt to different installation conditions.

Easy installation: Although the size of worm gear reducers may be relatively large, their installation process is relatively simple, and they are usually equipped with complete installation accessories and instructions to facilitate users to install and debug.

-

Authenticated user

-

Authenticated user

JIE intelligent transmission solution releases JIE intelligent transmission solution

hot news

- Research丨Lv Tie, a researcher from the Academy of Social Sciences, visited JIE for research and guidance >

- Academician|Mathematician Academician Sun Binyong inspects JIE future factory >

- Research | Lu Wuhu, vice chairman of the Municipal Federation of Trade Unions, investigates the JIE future factory >

- Research | Li Yongwei, Director of the Technological Innovation Department of the Provincial Department of Economics and Information Technology, investigates the future factory of JIE >

- Research | District Science and Technology Bureau Secretary Cao Xiaoxiang investigates JIE future factory >

- 33 | There is a kind of happiness called party care >

-

- Sharing Center

- Member Sharing

- Exclusive Sharing

- Public Sharing

Official Website

Official Tiktok

Official WeChat

Copyright © 2022 Hangzhou Jie Drive Technology Co., Ltd. Zhejiang ICP No. 16044538-4

English

English 简体中文

简体中文

Official Tiktok

Official Tiktok Official WeChat

Official WeChat